As I’ve mentioned in my manifesto, customer experience has a lot of similarities with the quality movement of the 1980s. A few process improvement methodologies that evolved from that quality (TQM) movement can be found across many large organizations.

In particular, there are a lot of firms using Six Sigma and Lean methodologies. So it’s no surprise that I’m often asked to comment on how Six Sigma and Lean can be integrated with customer experience efforts.

Let me start by providing a very, very simplified description of both methodologies

- Six Sigma: This methodology attempts to eliminate defects by redesigning processes. Experts who are trained in the use of several tools (e.g., black belts, green belts) drive the effort, often on an ad-hoc or consulting basis inside of a company. It evolved from Deming’s plan-do-check-act cycle.

- Strength: Data-driven approach that can create consistent, repeatable processes even in complex environments

- Weakness: Dependent on a few trained specialists and sometimes focuses too much on consistency and not enough on customer needs

- Lean: This methodology strives to eliminate waste, in time and resources, for both the company and the customer. Employees are taught to apply some straightforward tools and are expected to identify and make changes as part of their normal activities. It evolved from Toyota’s “just-in-time” manufacturing approach.

- Strength: Engages entire organization in the process; creating a common vocabulary and focus for cultural change

- Weakness: Employees may not have the skills or enough time to understand anything beyond very superficial customer needs.

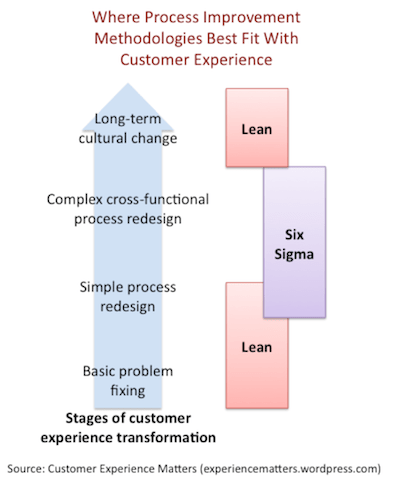

Given the relative strengths and weaknesses of these methodologies, they are each best used at different stages in the customer experience transformation journey.

If your company is focusing on customer experience and uses one of these methodologies, then make sure to look at these areas:

- Customer insight. Neither of these methodologies is inherently customer-centric, so you need to infuse more customer focus into them. Make sure whatever methodology you use is augmented with very strong insights of customers’ needs — whether customers can articulate them clearly or not.

- Employee experience. Both of these methodologies have the possibility of negatively impacting employee morale. In Six Sigma, employees undergo change and in Lean they are oftentimes asked to do additional work on these projects. Since employee experience leads to customer experience, it is critical that executives monitor the effect on employees.

The bottom line: Customer experience transformation requires process change.

This blog post was originally published by Temkin Group prior to its acquisition by Qualtrics in October 2018.